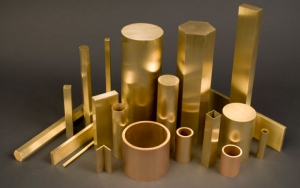

Brass Alloy Specifications

Brass Alloy is made of a series of copper alloy and a maximum of 40% zinc, the ratio of the two in the alloy determines the type of brass. Some types of brass alloys are also called bronze, although bronze is an alloy of copper and tin. Brass has an almost yellow color that is similar to gold and is resistant to turbidity and staining and does not oxidize easily.

This metal is used in different places because of its special applications and shape and color: for example, because of its yellow color in decoration, because of low friction in the locks of locks and because of its acoustic properties in musical instruments such as horns. has it.

When man did not yet know the metal zinc, he produced brass by melting copper with calamine (zinc metal ore). Brass is usually more malleable than copper and zinc, and its melting point is approximately 900 to 940 degrees Celsius. Of course, its hardness and softness can be changed by changing the ratio of copper and zinc mixture.

Copper in brass gives it antimicrobial properties through oligodynamic effect. That is why brass is used as a handle and other common metals in hospitals.

Today, the purchase of brass metal is done second-hand and recycled because almost 90% of brass metals are recycled. Brass metal has little magnetic property and can be easily separated from the metals with which it is usually mixed.

In this way, the isolated brass is recycled. The average density of brass is 8.4 grams per square centimeter.

Types of brass

- Admiralty brass: contains 30% zinc along with 1% tin

- Alpha brass: Contains less than 35% zinc, which can be used for high pressure, impact and cold work. The crystal structure of this type of brass is FCC.

- Beta brass: Contains 45% to 50% zinc, which is harder and more resistant to heat, pressure and impact.

- Alpha-beta brass: contains 35% to 45% zinc suitable for heat

- Aluminum brass: Contains aluminum and has a high resistance to corrosion, which is used in the manufacture of European coins.

- Arsenic brass: Contains arsenic and aluminum. This brass contains 0.03% arsenic to improve corrosion resistance against water. Like other types of brass, arsenic brass is bright yellow, firm and malleable. This alloy is also a metal suitable for use in plumbing. Other uses include heat exchangers, decorative utensils, tanks, pipes and radiators, electrical terminals, lamp and socket connections, and locks and cartridge covers.

- Bullet brass: contains 30% zinc

- Common brass: Contains 37% zinc, cheap and suitable for heat-free work

- High brass: contains 35% zinc and 65% copper, with high flexibility, used in the manufacture of springs and screws.

- Lead brass: The same alpha-beta brass with some lead.

- Low brass: Contains 20% zinc, with a yellow color close to gold

- Navy brass: Similar to Admiralty brass with 40% zinc and 1% tin

- White brass: contains more than 50% zinc, very brittle

- Golden brass: The softest metal is brass with 95% copper and 5% zinc, which is used in the manufacture of ammunition. This type of brass, which is a gilded metal, can be hammered or easily turned into the desired shape. This will make selling brass sheets easier and easier. Its unusual bronze color and ease of use in handicraft projects are ideal. Some of its applications include architecture, lattice making, jewelry making, decorative decoration, badges (medals), handles, marine hardware, automatic body, pencil and etc.

Brass alloy

Brass is actually a term that refers to different types of metal alloys based on copper and zinc. Brass alloys are usually popular in metalworking due to their high strength and corrosion resistance.

Brass, like bronze, is an alloy that contains copper and uses zinc instead of tin. Both brass and bronze may contain small amounts of other elements such as arsenic, lead, phosphorus, aluminum, manganese and silicon.

Note, however, that the properties and consequently the applications of brass may vary depending on the ratio of copper to zinc and other alloys used. This alloy is usually pale gold, silver to red and is used in home decoration due to its special beauty and shine.

Brass alloy features

Brass is usually more malleable than copper and zinc, and its melting point is approximately between 900 and 940° C. Of course, its hardness and softness can be changed by changing the ratio of copper and zinc mixture.

With the least amount of zinc, brass can be easily cooled, boiled and cast. The high copper content also allows the metal to form a protective oxide layer (patina) on its surface that further protects it from corrosion, which is a valuable property against moisture.

Brass is a non-magnetic, low-friction alloy, and its acoustic properties can be used in many brass instruments. Architects also know the beauty value of brass, as they can use it in a range of colors from dark red to golden yellow. The brass is almost yellow in color, which is similar to gold.

Brass is also resistant to turbidity and staining, ie it oxidizes later. Today, almost 90% of brass metals are recycled, because brass metal has little magnetic property and can be easily separated from the metals that are usually mixed with it. In this way, the isolated brass is recycled.

Brass sheets have good electrical and thermal conductivity (their electrical conductivity can be as much as 23% to 44% pure copper) and are resistant to abrasion and sparks. Copper in brass (through oligodynamic effect) gives it antimicrobial properties and causes the use of brass in bath utensils, metal utensils in hospitals.

Low quality brass:

Increasing the percentage of zinc in the composition of low-grade brass metal increases its strength and ductility and changes its color from yellow to red, gold or green, and this color change depends on the percentage of zinc added.

Deformation of this alloy is possible in the temperature range of 730 to 900 degrees Celsius. Low-grade brass has a high ductility and malleability at room temperature.

High quality brass:

High-quality brass has more zinc in its composition, which increases the amount of zinc in the composition of this metal, increases its strength and increases its ductility to a considerable extent.

Classification by difficulty

Brass sheets and coils are divided into three categories based on their hardness, which are effective in selling them.

-

First category: spring brass

These brass alloys have the highest hardness, which is often available in the form of coils, with a thickness between 0.3 to 1mm and a width of 3.5mm, and they are mostly used in the electrical industry.

-

Second category: semi-hard brass

These brass alloys are semi-hard. Due to their lower percentage of copper, these sheets have less flexibility compared to soft brass and are often produced in the form of sheets with a thickness of 0.3 to 20mm with a maximum width of 660mm and a length of 2 meters. These brass alloys are important factors in buying brass plates and sheets.

-

Third category: soft brass

Brass alloys in this category, with about 70% copper, have the softest and most flexible state of brass. These alloys are available in two types of sheets from 0.3 to 1.5mm thick with a width of 660mm and coils from 0.4 to 0.8mm thick and 660mm wide.

The high percentage of copper and softness of this type of brass makes this alloy weldable, and this property has made this type of brass the most widely used type. It is mostly used in the production of consumables and decorations such as samovars and radiators.

How to make brass alloy

6 steps are used to make brass alloy.

-

Step 1: Melt copper

In the first step, the copper must be melted. The melting points of copper and brass are different. Zinc has a melting point of 907 and copper has a melting point of 1083 degrees Celsius. Therefore, after smelting copper, zinc is added in the right proportion to brass.

-

Step 2: Add Add-ons

At this stage, to reach the desired alloy of brass, aluminum, lead and silicon are added in appropriate amounts.

-

Step 3: Formatting

Now that the alloy has become molten and has been mixed with the necessary compounds, it must be poured into the mold and cooled for molding. Slabs or billets are made here.

Direct method can be used for processing billet or alpha-beta brass. In this method, the billet is processed by hot extrusion into wires and pipes. Hot extrusion means the same as hot forging.

If hot forging is not used for the billets, it must be reheated and hot rolled to reach the desired thickness. In the hot rolling method, the billet is inserted into the steel rollers and reaches the desired thickness under pressure.

After cooling, a thin layer is removed from the metal surface to eliminate its defects and remove surface oxide. A milling machine can be used for this purpose.

-

Step 4: Cold rolling

Cold rolling increases the strength and durability of the metal. This can be repeated until the metal reaches the desired thickness. 2.5 mm thick slabs can be reheated before cooling. This is very effective in preventing oxidation.

-

Step 5: Cut the sheet

At this stage, the sheets are cut with scissors to be classified in the desired width and length.

-

Step 6: Wash the brass

In the last step, the final product is washed with special chemicals to remove copper oxide from it.

Usage of brass alloy

-

Decorative Objects

brass, due to its bright and attractive appearance, is usually used to make home decorations, clothing decorations, etc. The most famous home decorations include antique candles and brass sculptures.

-

Architecture

The inherent durability and corrosion resistance of brass make it a popular alloy in architecture and is often used in plastering columns as well as piers. Special brass alloys are also used to repair or renovate historic buildings around the world.

-

Electricity and plumbing

brass is often used as one of the elements used in two important home systems, namely plumbing and electricity. Applications of brass alloys in this field include sockets and electrical switches, as well as valves and various pipe fittings such as elbows, plugs and couplings. Brass is often used in cases where it is important not to spark, such as fittings and tools near flammable or explosive materials.

-

Cars and vehicles

Brass alloys show minimal friction in settings that require metal-to-metal contact and are therefore often used in mechanical devices. This alloy is used in gears, locomotive axle boxes and brass marine engines.

-

Musical Instruments

Throughout history, brass has been used to produce many of the most famous brass instruments, including trumpets, horns, trombones, and tuba. Because this alloy is very flexible, and since instruments must be precisely shaped for proper performance, brass is suitable for this purpose. Electric instruments such as electric guitars and violins also have brass components inside.

-

Tools

One of the most common uses of brass is to make brass hammers. Although we usually use iron or steel hammers in our daily work, brass hammers are used for professional and specialized work in the metalworking industry.

Brass hammers are softer than metals such as steel and are a good option for working on steel without damaging it. They can also be used for strong metals such as gold. brass is also used in many tools such as flat knives and so on.

-

Key

brass has a high resistance to corrosion, and since the key is a very precise tool in nature and should not be easily worn or deformed, brass is usually used to make it.

-

Sculpture

The construction of brass sculptures has been common for thousands of years. This application is also due to the high ductility of brass, which is ideal for sculpture. The use of brass allows the artist to put any shape and appearance he wants on the sculpture.

Ways to detect brass metal from copper

As mentioned, brass alloy is made of copper and zinc. The color of brass is so different from the color of copper that they are easy to distinguish. But it may be difficult to distinguish these two metals in some situations. For example, in cases where brass contains high amounts of copper alloy.

One way to diagnose is to clean the metal you are holding well first. So that no contamination remains on its surface. Then place it under a direct light. The color of pure copper is reddish-brown, but brass has a range of yellow colors.

Different ratios of these metals produce different colors. But the most common color of brass is yellow or yellow-brown, which is more similar to bronze.

In some brass, the percentage of copper is higher. This causes the brass to look orange or red or reddish brown. This type of alloy is commonly used in jewelry making, decoration and pipe making. You will usually have doubts about distinguishing this type of alloy from brass to copper.

Another point in distinguishing these two metals is that when the color of the metal is more orange, yellow and gold, it is a sign that the metal is brass and not copper. Also, if the metal has high levels of zinc, it can be seen in light golden, yellowish white or gray. But we must note that this alloy is very rare and if it is used, it is mostly used in jewelry.

Another simple way to distinguish copper from brass is to test the hardness of the metal. It is true that brass is an alloy of copper, but it is harder than copper. So it is enough to recognize with a stroke that your metal is copper or brass.

For Buy Copper and find best price of copper in Iran , contact us.