Specifications of copper powder

Copper is a very flexible metal and is widely used for its thermal and electrical conductivity. Copper is used in electrical wires as well as in combination with other metals to form various alloys (for example in combination with tin to obtain a bronze alloy). When the metal is exposed to air, the outer layer of the metal slowly turns to black oxide.

Copper in powder form is one of the most widely used types of copper that is used in various industries. Copper  powder is one of the few metals that exist in nature in the form of metal (native metal), copper is a member of group 11 of the periodic table. Copper powder is produced in different granulations from -63 microns to 250 microns.

powder is one of the few metals that exist in nature in the form of metal (native metal), copper is a member of group 11 of the periodic table. Copper powder is produced in different granulations from -63 microns to 250 microns.

Copper powder is produced in the form of granules and flakes, most of which are used in the form of flakes. It should be noted that copper powder is not used in pure form in industry and is mostly used for alloying with other metals .

Adding this powder to the alloy is done in the form of mixing or infiltration. Copper powder alloy with tin, zinc, nickel and other metals is used to make friction parts.

The use of copper powder can be mentioned as an alloying element in iron powder to be able to give more strength to the desired material than copper and iron alloy by mechanical properties, which can be more durable during cooking.

Technical specifications of copper powder

| Product Name | Copper powder |

| Chemical symbol | With |

| Molecular weight | 63.55 g / mol |

| melting point | 1085 ° C |

| Boiling point | 2562 ° C |

| Density | 8.96 grams per cubic centimeter |

| Appearance | Reddish brown |

| Solubility | Insoluble |

Physicochemical properties of copper powder

- Corrosion and heat resistance

- High electrical conductivity

- Ductility

- Good strength

- Hammering

- Degree of purity

- Flexibility

The largest importers of copper powder

- Germany

- Italy

- China

- United States

- Canada

The largest exporters of copper powder

- Germany

- Italy

- United States

- Russia

- England

- Taiwan

- Japan

Copper alloys

Among the properties of copper is its wide range of alloying power with various metals and it is one of the few metals that is consumed in pure form more than alloy. If some copper elements are added, its properties are improved and its efficiency is improved.

By adding aluminum, chromium, iron, manganese, nickel, phosphorus, silicon, tin and zinc, it increases its corrosion resistance. The addition of aluminum, cadmium, silver and tin increases its wear resistance and improves the lead, silicon, tellurium, and zinc machining power of copper.

The most commonly used copper alloys are yellow and red brass, which is obtained by adding tin, and bronze or bronze, which is obtained by adding zinc. Other copper alloys are copper and nickel alloys, which are silver in color and are used in coinage. By adding one percent tin to red brass, navy with high corrosion resistance is obtained.

Methods of producing copper powder

Copper powder companies use the following methods to produce this powder :

-

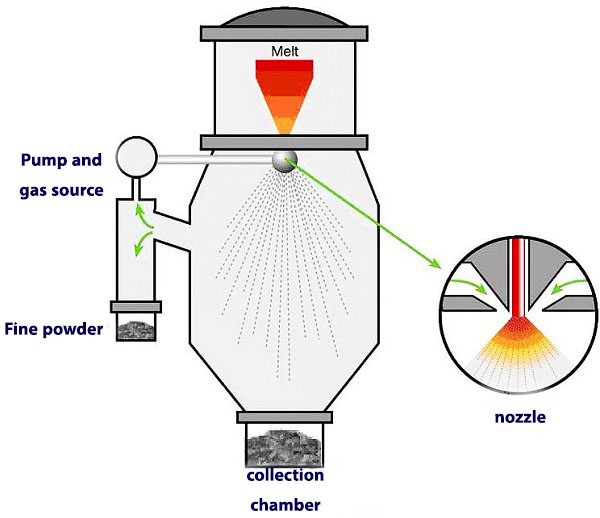

Atomization

In this method, copper is melted and the liquid metal is passed through the holes, where it is cooled by the rapid flow of gas or liquid, which is usually water, so that the molten metal is crushed into small particles that quickly They become solid. Particle size and shape are particularly affected by the atomic environment, pressure, and flow rate.

Small controlled additives of oxidizing elements such as phosphorus also affect the size and shape of particles. After atomization and annealing in the atmosphere, reductants are added to the compound to reduce any surface oxide generated during atomization, and the product obtained is ground, mixed, and mixed to achieve the required particle size distribution.

The purity of the product depends on the raw material. Because melt refining is not generally done before atomization. Purity is generally more than 99%. This powder can be made spherical or irregular. Particle size and shape, bulk density, flow and resistance are affected not only by atmospheric variables but also by oxidation control during atomization.

-

Hydrometallurgy

The hydrometallurgical process can be used to produce copper powder from copper cement, concentrate or copper scrap. Copper from these materials is washed with sulfuric acid or ammonia solutions and the charged solution is separated from the residue by filtration. As the hydrogen decreases under pressure, copper precipitates from the solution.

The resulting powder is pumped into a centrifuge in which the powder is separated from the liquid and washed. Wet copper powder is reduced in the atmosphere, ground, and sorted and mixed to achieve the desired particle size distribution.

The physical properties of the powder can vary considerably. The temperature and time of reduction and the amount of acrylic added have a significant effect on the properties of the powder.

-

Electrolyse

Electrolytic copper powder is used to create loose copper powder deposition in accordance with the following principles that are used in plating with modified conditions.

The formation of powder deposits that adhere to the cathode is directly related to the low concentration of copper ions in the electrolyte, high acid concentration and high current density at the cathode. Addition of colloids such as glucose leads to the formation of a uniform copper precipitate. The raw material of copper is pure cathode.

The properties of the powder depend on a number of variables including the concentration of sulfuric acid and copper sulfate, the type and amount of additive, the electrolyte temperature and the current density.

After deposition, the powder is washed to remove all traces of electrolyte, reduced in the atmosphere, mixed with high-speed impact mills for cluster analysis, screening, classification, and particle size distribution.

Electrolysis copper powder is a high purity powder and on average contains more than 99% copper. The shape of the powder is dendritic. A wide range of powders with different apparent densities and high strengths can be obtained with this method.

Also, this method can change different parameters during powdering and has a lower cost. Copper nanopowders are produced by electrolysis and generally have smaller particles. In the electrolysis method, the powders are cleaner.

-

Solid state reduction

In this method, the oxides are first ground to control the particle size and then cracked by a gas, usually carbon monoxide , hydrogen or natural gas, and crushed at temperatures below the melting point of copper.

Particle size and shape can be controlled over a relatively wide range by changing the particle size and shape of the oxides, reducing the temperature, pressure and gas flow. The resulting powder is ground, classified and mixed to the desired specifications.

The purity of the product obtained depends on the purity of the oxide used. Because there is no purification during the regeneration process. In general, the powders produced by this method are porous and have a high density and strength.

Other methods of producing copper powder

-

Production of alloy powders

Most of the alloy powders used are produced by atomization. Pre-mixed powders are a mixture of the desired composition, with or without lubricant, that are formed during the baking of the alloy.

Pre-alloy powders are produced by atomizing the alloy composition by the methods mentioned for the production of copper powder. Pre-alloy powder can be turned into a powder with desired specifications by baking the mixture and grinding.

-

Production of bulk powders

The powders previously discussed are granular and are primarily used to produce powder metallurgy (P / M) components. Bulk powders are used for other purposes. Although pure copper powder is produced in the form of shells, most shell powders, so-called “golden bronze” powders, are made from copper alloys with zinc and aluminum.

Usages of copper powder

- This metal in powder form is often used in electrical and electronics industries due to its excellent electrical and thermal properties.

- The production of lubricants from this powder is probably the most common use of copper powder and about 70% of the total production of copper powder in granular form is used for this purpose.

- Copper powders are also used in non-structural applications such as soldering, cold soldering and mechanical plating, as well as for making medals, decorative metal products and various chemical and medical devices.

For example : Atomized copper powder is very suitable for powder metallurgy (P/M) applications. Because it has high flow rate and good resistance. This powder can be used in electronic and electrical applications that require high conductivity, provided that the copper powder is of high purity.

Electrolytic copper powder, due to its high purity, is especially suitable for P/M components in the electronics and electrical industries where high electrical and thermal conductivities are required. However, it is also suitable for most other P/M applications.

- Construction uses such as: copper pipes in piping, types of handles

- Firefighting equipment and other firefighting equipment

- X-ray work coatings and insulating insulation

- Central heating systems and oil and gas transmission lines

- Mechanical engineering, with instrument makers

- Vacuum lamps and cathode ray tubes in the microwave

- Production of copper parts and segment production industries

- Automotive Industries Brake pads and clutch plate

- Water storage and transfer, sewage piping

- Production of brass products

- Water filters and coolers

- Pipe clamps

- Dietary supplements and fungicides

- Heat exchangers and heat exchangers

- Agriculture industry

- Combustion welding

- Cut diamonds

- Military industries

- Chemical industry

- Sculpture industries

- Leather and leather industry

- Medicine and Veterinary Medicine

- Paint industries

- Paper industry

- Shipbuilding industry

- Food industry

- Metalworking industries

- Mechanical industries

- Diamond cut

- Aviation and marine industries

- Industrial Machinery Industries

- Casting industry

- Wiring units

- Electric magnets

- Copper powder in bodybuilding

Safety tips regarding copper powder

- Problems such as fever and chills, nausea, vomiting and swallowing can irritate the gastrointestinal tract.

- Inhalation of oxide vapor causes inflammation of the upper respiratory tract.

- Inhalation of industrial copper powder dust irritates the nasal mucosa.

- Copper particles are harmful to the skin and eyes.

- Copper as a carcinogen has not yet been proven.

Prolonged presence of copper in aquatic and terrestrial environments or copper processing can cause the release of copper in the environment, which increases the likelihood of toxic effects on aquatic organisms.

Forms and reactivity of copper powder

The shape of the particles produced depends on the method of production. Copper powders produced by the methods discussed can be spherical, irregular or dendritic. Shape affects density, surface, permeability and flow characteristics.

Porosity also varies depending on the production method and affects the density. Internal pores reduce density but have no share in particle activity. Surface-connected pores reduce density but also increase effective surface area and activity.

Surface area depends on particle size, shape and condition, and particle size distribution. The smaller the particles, the higher their specific surface area. An irregular particle will have more surface area than a spherical powder of the same size.

Surface roughness and porosity attached to the surface can increase the specific surface several times more than the area associated with size and shape factors. The activity of a particle generally increases with increasing surface area. The specific level is remarkable. Because reactions like cooking start from a certain level.

It is better to know:

The hydrometallurgical process generally produces a powder with fine particle size, low bulk density, and high strength. With these features, it is especially suitable for use in friction materials such as car brake pads. Powders produced by solid state reduction have similar properties to atomic powders and are suitable for similar applications.

Copper powders are used in copper graphite compounds, which have low contact strength, high current carrying capacity and high thermal conductivity to make brushes in motors and generators and as moving parts of rheostats, switches and washers carrying current.

These powders are also used to make electrode tools for machining the electrical discharge of complex molds. Copper powder is selected due to its high electrical and thermal conductivity.

Pure copper is also used in non-electrical P/M applications. An interesting example is a copper blade impregnated with oil to extend the useful life of a pocket knife. Copper as nanoparticles can also be synthesized in ethylene glycol (EG) using copper sulfate as a precursor and vanadium sulfate as an unusual reductant.

Metal nanoparticles can also be obtained using microorganisms through biosynthetic processes, which have common advantages over chemical synthesis methods. Biosynthetic processes are environmentally friendly and no toxic chemicals or introduction are required for these processes.

for buy copper from Iran and get copper price please contact us.

i wanna know the supplier of cooper podwer. i am going to export it to china then import other cargo back iran.