Aluminum alloys

Aluminum is the thirteenth element of the periodic table, denoted by the symbol (Al). Aluminum is white, soft, non-magnetic and conductive. Aluminum is the third most abundant element in the earth’s crust (after oxygen and silicon). About 8% of the earth’s crust is made of the most commonly used metal, aluminum. Aluminum alloys are one of the most diverse alloys that have many usages due to their light weight and high durability.

Today, due to the great potential and usages of aluminum metal in the production of various types of metal parts and the growing expansion of industries that use this metal as a parent metal in the supply of raw materials. The market for alloy aluminum has also become wider and wider.

Aluminum as a parent metal has the unique property of combining special chemical elements to show more pronounced coordinates and capabilities than other metals. The price of aluminum metal in the Iranian market varies depending on the type of alloy. In order to obtain the desired properties and characteristics, aluminum alloying operations are usually performed during the melting and casting process.

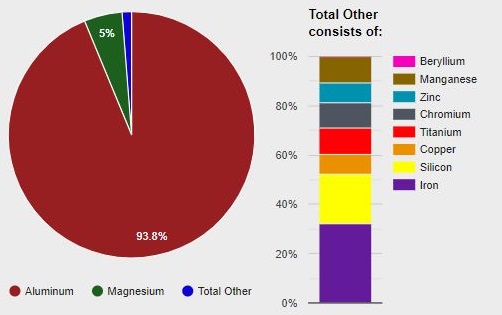

Certain types of aluminum are formed with the main property of aluminum, which usually contains 90-96% aluminum, and in addition has one or more other elements that have been added to aluminum to improve its properties. Alloy aluminum usually includes several minor alloying elements in addition to the main alloying elements, which have a small amount but have a great impact on their properties.

Definition of alloying

In general, the word alloying means adding one or more elements or combinations of them to aluminum to achieve a specific set of properties. The change of properties due to the addition of these elements depending on the type of base element and the alloying elements added can be exclusively dependent on an element or a combination of added elements.

Since the strength and hardness of aluminum is always less than its alloy types, aluminum alloy is generally used in industry and pure aluminum is usually used in more special usages.

The reason for the expansion of this industry

According to extensive research conducted by researchers in the field of materials and metallurgy, aluminum metal is the best known metal in the world for obtaining various alloys due to maintaining its basic properties during alloying and improving its quality coordinates.

Aluminum alloys in different categories can cover a variety of industries. Many researches have been done in this field, most of which indicate that in the initial studies of materials for the production of various parts, the first channel to obtain the best raw materials is definitely to refer to the information of aluminum alloy, because most likely one of them as materials. The initial fabrication of the part passes the initial tests.

Specifications and features of aluminum alloy

-

Corrosion resistance

One of the characteristics of aluminum in its pure form is corrosion resistance. Attention increases.

Many aluminum alloy grades have high levels of atmospheric and chemical corrosion resistance due to the natural formation of the oxide layer adhering to the surface. This feature is more pronounced in 1xxx, 3xxx, 5xxx and 6xxx series alloys, which we will explain in the following.

-

Capability in thermal conductivity

Aluminum alloys have a very high thermal conductivity and due to the fact that they melt at a lower temperature than steel, but in the presence of fire, the temperature of aluminum alloy rises at a much slower speed.

-

Capability in electrical conductivity

Aluminum and some alloy aluminum have a very high electrical conductivity and in this respect are among the second most conductive metals after copper. One of the main reasons for the high approach of the electrical and electronics industries is their capability and its more affordable price than copper.

-

Appropriate ratio of strength to weight

Aluminum does not show much change in weight after alloying, in other words, the high strength of aluminum alloy relative to its weight is one of the main factors in its selection compared to other metals. Low density aluminum is suitable for making engineering alloys.

Although their strength is not as high as that of steels, the strength-to-weight ratio is high, and for this reason commercial aluminum alloys abound. The strength of most of these alloys can be increased by hard deposition or hot work.

-

Resistance to failure

By alloying, the level of failure resistance in alloy aluminum is significantly increased or their so-called toughness is increased. Many aluminum alloys are tough and are used in usages that require brittle fracture resistance and crack growth.

-

Very high workability

Aluminum alloy after the alloying process shows a very high flexibility and ability to work, that both by extrusion process and by a variety of machining and cnc machining can be achieved very precise specialized parts. Basically, one of the features of aluminum is that by making it alloy and obtaining different types of aluminum alloy, the amount of workability in this metal can be increased.

-

High connectivity

Aluminum alloys can be bonded to other surfaces by extensive bonding methods such as welding, soldering, riveting and even gluing and nailing.

-

Recyclability

Aluminum alloys have a very, very low percentage of non-recyclable castings, and the production residue of each category can be easily recovered using the process of melting and re-casting, and after recycling, materials of the same quality can be obtained.

Aluminum alloy groups

In general, aluminum alloys are divided into two categories in terms of production method, with climbing alloys accounting for more than 80% of the total volume of aluminum alloys used.

-

Alloys wrought

Rolling alloys according to the standard ( Associatian Aluminum ) AA are divided into eight groups 1xxx to 8xxx depending on the type of constituent metals; Workable aluminum alloys are alloys that are mechanically shaped to the desired shape.

Some of these alloys can be reinforced by special heat treatment and others are not heat treatable. Workable alloys are divided into eight groups based on their main alloying element, and each of the alloys in each group is named by the AA (Aluminum Society) with a four-digit number .

-

Alloys Casting

Aluminum are alloys that are molded into the desired shape. These alloys are also some heat treatable and some non-heat treatable. Each of these alloys is named by AA with a four-digit number placed between the fourth and third digits to the left of a dot .

Types of aluminum alloys

-

Aluminum – copper alloy

Its brand name is Dur Aluminum . The hardness of this alloy reaches a maximum despite 5.7% copper. Silicon and magnesium alloying elements are sometimes used. Duralumin is widely used in lightweight structures and the aircraft industry. The corrosion resistance of doraluminins is lower than that of aluminum. They often protect the duralumin surface with a thin coating of commercial pure rolled aluminum. Sometimes the C code is introduced.

-

Aluminum – magnesium alloy

Its brand name is Alumag . The amount of magnesium is less than 10%. The main property of alumag is its good corrosion resistance.

As the amount of magnesium increases by more than 10%, its corrosion resistance decreases sharply. The main usage of these alloys is due to their good corrosion resistance, high lightness and indirectly good polishing ability and maintaining this polish in them. For this reason, amalgam alloys are used in architectural and decorative works. Manganese and silicon alloys are sometimes used. Sometimes introduced with the code G.

-

Aluminum – silicon alloys

Their brand is Alpax . Increasing silicon without greatly reducing its ductility increases the castability of aluminum and at the same time increases its mechanical strength. This alloy has 12 to 13% silicon and its hardness can be increased by heat treatment. Sometimes 7% silicon and 3% magnesium are used. It is used in the preparation of oil tanks for internal combustion engines, washing machine parts, radiators and electrical appliances. Sometimes the code S is introduced.

-

Tin ( Sn )

This element effectively improves the anti-friction property, so it is useful in bearing usages. Cast alloys may contain up to 25% tin. Increasing the amount of tin improves the machining properties and affects the hard deposition action in some alloys.

-

Lead (Pb)

The presence of lead and its properties in amounts of more than 0.1% improves the machining properties.

-

Iron (Fe)

This element improves the resistance to hot cracks and reduces the adhesion of the piece to the mold in injection molding. Increasing its percentage reduces the formability. It may also react with other elements added to the melt to form complex intermetallic compounds or sludge.

-

Manganese (Mn)

This element is used in small amounts to control the destructive effect of iron in brittle phases. It contains about half a percent of iron. Manganese is used as an alloying element in workable alloy compounds.

-

Chromium (Cr)

The addition of chromium causes intermetallic compounds, and because these compounds have very little solubility in the solid state, they prevent grain growth. Chromium in some alloys improves corrosion resistance and in higher amounts increases the sensitivity to rapid cooling.

-

Nickel (Ni)

This element together with copper increases the resistance to high temperature and also reduces the coefficient of thermal expansion.

-

Phosphorus (P)

This element causes germination and refining of the primary silicon phase in hyperrotective aluminum-silicon alloys.

-

Titanium (Ti)

This element is used to fine-tune the structure in cast aluminum alloys. Titanium is usually used in small quantities.

-

Strontium (Sr)

This element is used to modify aluminum-silicon eutectic alloys.

Series of aluminum alloys

Aluminum alloys are one of the most diverse alloys that have many usages due to their light weight and high durability. Aluminum alloys are divided into 8 general series, which include 1000, 2000, 3000, 4000, 5000, 5000, 7000 and 8000 serie

Alloy aluminum alloy in brief |

|

| Series or category | Major composition |

| 1xx.x | Aluminum is almost pure |

| 2xx.x | Aluminum and copper alloy |

| 3xx.x | Aluminum contains copper, silicon and a little magnesium |

| 4xx.x | Silicon aluminum |

| 5xx.x | Aluminum and magnesium alloy |

| 6xx.x | Alloys with a combination of magnesium, silicon and aluminum |

| 7xx.x | Alloys with a combination of zinc, aluminum and magnesium |

| 8xx.x | Aluminum alloy with less conventional elements such as tin and lithium |

1000 series of aluminum alloys

The 1000 series aluminum alloys contain at least 99% aluminum . This series of aluminum alloys has very high corrosion resistance, high electrical and thermal conductivity, machining acceptance, relatively low mechanical properties and weldability. Also, this series of alloys are soft and are used in works such as making foil packages for food, electrical connections and welding wires

-

Properties and usage of 1050 aluminum alloy :

In naming 1xxx series aluminum alloys, the last two digits represent the percentage of purity of the alloy. In fact, 1050 is an alloy with 99.5% aluminum. This alloy is also known as AA1050A, S1B and A91050.

1000 series alloys do not have very high strength due to the lack of alloying elements. Naturally, 1050 is no exception to this rule and its yield strength is only about 85MPa. This alloy is one of the series of heat treatment alloys and its strengthening is done through hard strain operation.

Due to its low mechanical strength, 1050 aluminum alloy has good ductility and is easily formed by the process of stretching, rolling and extrusion. But this alloy does not have good machining capability.

Aluminum is inherently corrosion-resistant metal. As soon as the metal is exposed to air, it oxidizes to form a thin, sticky, dense layer that prevents corrosion. This layer is so strong that it only dissolves in strong acids and bases such as chlorine and some hydroxides. It is said that this protective layer can withstand pH solutions between 4.5 and 5.8. If the protective layer of the alloy is damaged by wear, a thin layer forms again and protects the alloy against corrosion.

In terms of welding capability, 1050 has a good weldability and can be welded with most arc and gas welding methods. For welding 1050 aluminum on its own or an alloy of the same subgroup, it is recommended to use 1100 filler welding wires. Is.

Physical properties of 1050 aluminum alloy :

جدول ۱

Mechanical properties of 1050 aluminum:

جدول۲

Chemical composition of 1050 aluminum alloy:

جدول۳

1050 alloy usages

Aluminum 1050 is an alloy with a very shiny surface, high purity and low strength. This alloy has high electrical and thermal conductivity. Therefore, it can be a good option for parts with these features, including:

- Electrical conductor components such as power cords and sheaths

- Reflective pages

- Food industry containers

- Architectural flashes

- Chemical plant equipment

-

Properties and usages of 1060 aluminum alloy

Usages properties of 1060 aluminum alloy with chemical elements is suitable for making chemical industry equipment with the best use. Aluminum alloys are known for their high corrosion resistance properties. These alloys are sensitive to high temperatures and experience increased resistance to ground temperatures. Aluminum is a good low temperature alloy. 1060 low-strength aluminum alloy and pure aluminum alloy with suitable corrosion resistance properties.

Chemical composition of aluminum alloy 1060

| Alloy name | Ingredients ( weight percentage ) | considerations | Other elements | AL% | ||||||||

| 1060 | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ti | V<0.05 | Each | Total | Min 99.6 |

| <0.35 | <0.25 | <0.03 | <0.03 | <0.03 | – | <0.05 | <0.03 | <0.03 | – | |||

Physical properties of 1060 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 1060 | 69 | 26 | 646 | 657 | 900 | 23.6 | 2.750 | 27.8 | 234 | 62 |

| SPECIFICATIONS | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.7 g/cm3 | 0.0975 lb/in3 |

| melting point | 649°C | 1200° |

Typical mechanical properties of 1060 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Hardship | shear strength | Fatigue strength |

| O | 69 | 28 | 43 | 19 | 48 | 21 |

| H12 | 83 | 76 | 16 | 23 | 55 | 28 |

| H14 | 97 | 90 | 12 | 26 | 62 | 34 |

| H16 | 110 | 103 | 8 | 30 | 69 | 45 |

| H18 | 131 | 124 | 6 | 35 | 76 | 45 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

Other characteristics Properties and usages of 1060 aluminum alloy

| ASTM B209 | ASTM B210 | ASTM B211 | ASTM B221 |

| ASTM B241 | ASTM B345 | ASTM B361 | ASTM B404 |

| ASTM B548 | SAE J454 | ASTM B483 | ASTM B234 |

How to make and heat treatment of aluminum alloy 1060

- hard working

1060 aluminum alloy hardens only due to cold. Tempers H18, H16, H14 and H12 are determined based on the amount of work transferred to this alloy.

- Anil

1060 aluminum alloy can be annealed at 343 degrees Celsius (650 degrees Fahrenheit) and then cooled in air.

- Welding

Standard commercial methods can be used for 1060 aluminum. In this welding process, whenever necessary, it must be AL 1060. Good results can be obtained from the resistance welding process of this alloy through trial and error.

- forming

Aluminum 1060 can be formed between 510 and 371 degrees Celsius (950 to 700 degrees Fahrenheit).

- forming

1060 Aluminum can be formed perfectly with hot and cold work with special techniques.

- Machining

Aluminum 1060 is graded with relatively poor machining, especially in soft and smooth conditions. The use of high-speed lubricants or instrumentation or carbide is recommended for this alloy. Some cuts of this alloy can also be dried.

- Anil

Aluminum 1060 does not harden using heat treatment and can be annealed after the cold process.

- Heating

Aluminum / aluminum alloy 1060 can be heated between 482 and 260 degrees Celsius (900 to 500 degrees Fahrenheit).

Properties and usage of 1060 aluminum alloy

- In cases where good corrosion resistance and ductility are required and do not require high strength, this alloy is used.

- Aluminum 1060 is widely used in the manufacture of railway tank cars and chemical equipment.

- One of the most common uses of this alloy is to make equipment and consumables in chemical processes. The annealing temperature of this alloy is 345 degrees Celsius.

-

Properties and usage of 1100 aluminum alloy

Aluminum sheets 1100, pure alloys or 1000 series alloys are alloys that are at least 99% pure aluminum. The most common 1000 series alloy is this alloy (1100 alloy). This alloy is commercially called pure aluminum. Aluminum alloy 1100 is soft and malleable and also has high workability and is very suitable for usages including severe shaping. Because in the process of forming, the 1100 aluminum sheet hardens more slowly.

Alloy 1100 is the most weldable aluminum alloy and has a tensile strength of about 85% of the 3003 alloy and has a significantly lower tensile strength than the 6061 alloy. Its initial form is usually in the form of a plate or wire, and its properties are not temperature dependent. Of all the aluminum alloys, this is the mechanically strongest alloy.

Chemical composition of 1100 aluminum alloy

| Alloy name | Ingredients (weight percentage) | considerations | Other elements | AL% | |||||||

| 1100 | Si+Fe | Cu | Mn | Mg | Cr | Zn | Ti | Be<0.0008 | Each | Total | Min 99 |

| <1 | 0.05-0.2 | <0.05 | – | – | <0.1 | – | <0.05 | <0.15 | |||

Physical properties of 1100 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| o – 1100 | 69 | 26 | 643 | 657 | 904 | 23.6 | 2.71 | 29.2 | 222 | 59 |

| H18 – 1100 | 69 | 26 | 643 | 657 | 904 | 23.6 | 2.71 | 30.2 | 218 | 57 |

Mechanical properties of 1100 aluminum

| Type of heat treatment | Tensile strength | Surrender strength | Increase the length of the sample with a thickness of 0.062 inches | Increase the sample length by 0.5 inches | Hardship | shear strength | Fatigue strength |

| O | 90 | 34 | 35 | 45 | 23 | 62 | 34 |

| H12 | 110 | 103 | 12 | 28 | 28 | 69 | 41 |

| H14 | 124 | 117 | 9 | 32 | 32 | 76 | 48 |

| H16 | 145 | 138 | 6 | 38 | 38 | 83 | 62 |

| H18 | 165 | 152 | 5 | 44 | 44 | 90 | 62 |

usage of 1100 aluminum sheet

- This type of aluminum sheet can be used as an excellent thermal conductor in various industries. Of course, it should be noted that it is also very suitable for conducting electric current.

- Although light weight, it shows high strength and durability.

- It is resistant to corrosion and has the ability to weld as well as bond with glue.

The main usages of this alloy in industries :

- General worksheet

- Low pressure panels

- Light bulbs

- car tag

- Heat Exchangers

- food plates

- Light reflectors

Properties and usages of 1145 aluminum alloy

This alloy is used in the manufacture of packaging foil, heat exchangers and also in insulation. Aluminum is very durable due to its corrosion resistance. They are sensitive to high temperatures in the range of 200 to 250 degrees Celsius (392 to 482 degrees Fahrenheit). High temperatures tend to reduce the strength of these alloys. However, the strength of aluminum alloys can be increased and converted to low temperature alloys.

Chemical composition of aluminum alloy 1145

| AN ITEM | CONTENT (%) |

|---|---|

| Aluminum, Al | 99.45 (min) |

| Copper, Cu | 0.05 |

| Manganese, Mn | 0.05 |

| Magnesium, Mg | 0.05 |

| Zinc, Zn | 0.05 |

| Titanium, Ti | 0.03 |

| Silicon, Si + Iron, Fe | Remainder |

Physical characteristics of aluminum alloy 1145

| SPECIFICATION | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.6-2.8 g/cm3 | 0.0939-0.1011 lb/in3 |

Mechanical properties of 1145 aluminum alloy

| SPECIFICATION | METRIC | IMPERIAL |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

Thermal properties of 1145 aluminum alloy

| PROPERTIES | Conditions | TREATMENT | T (ºC) |

|---|---|---|---|

| Thermal conductivity | 227 W / mK | H18 | 25 |

The equivalent materials of 1145 aluminum alloy are as follows

- AMS 4011

- ASTM B373

- ASTM B479

- QQ A-1876

Manufacture and heat treatment of aluminum alloy 1145

- Machining of aluminum alloy 1145

1145 Aluminum Alloy is a difficult alloy for the machine. Machining on the H16, 18 or 19 is a little easier using the cooler, softer mode.

- Alloy aluminum structure 1145

Aluminum 1145 has excellent forming quality and can be easily formed using all common forming methods.

- Welding of aluminum alloy 1145

The 1145 aluminum alloy welding capability is excellent in commercial methods such as TIG or MIG welding.

- Heat treatment of aluminum alloy 1145

Aluminum 1145 is not a heat curable alloy that hardens with cold.

- Cold work of aluminum alloy 1145

1145 aluminum alloy works easily in the cold. Very comfortable and soft, such as annealing, H12, 14, 16. It is much more difficult with obsessive-compulsive disorder, but it is still possible.

- Heat treatment of aluminum alloy 1145

This can be done at 343 ° C (650 ° F) for a reasonable amount of time and then cooled.

- Hardening of aluminum alloy 1145

Alloy 1145 hardens only with cold.

-

Properties and usage of aluminum alloy 1199

This ultra-pure grade with excellent anodizing, soldering and welding capabilities. Aluminum alloy 1199 has the highest purity of aluminum and the lowest amount of alloy. Aluminum is one of the most important metals due to its many properties. It is used in several fields such as automotive, aerospace, marine and engineering.

Because it is abundantly available, it is relatively cheaper than many metals. Aluminum 1199 is a malleable alloy with good corrosion resistance.

Chemical composition of aluminum alloy 1199

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 1199 | Fe | Si | Cu | Mn | Mg | Cr | Zn | Ti | V<0.005Ga<0.005 | Each | Total | Min 99.99 |

| <0.006 | <0.006 | <0.006 | <0.002 | <0.006 | – | <0.006 | <0.002 | <0.002 | – | |||

Physical properties of aluminum alloy 1199

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 1199 | 62 | 25 | 660 | 660 | 900 | 23.6 | 2.705 | 26.7 | 243 | 64.5 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.70 g/cm³ | 0.0975 lb/in³ |

| Melting point | 660°C | 1220°F |

Typical mechanical properties of aluminum alloy 1199

| Tensile strength | Surrender strength | Percentage increase | Hardship | Percentage reduction in cold rolling process |

| 45 | 10 | 50 | 15 | Annealed |

| 59 | 57 | 40 | – | 10 |

| 77 | 75 | 15 | – | 20 |

| 96 | 91 | 11 | – | 40 |

| 110 | 105 | 6 | – | 60 |

| 120 | 115 | 5 | 27 | 75 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Tensile strength | 115 MPa | 16700 psi |

| Yield strength | 110 MPa | 16000 psi |

| Poisson’s ratio | 0.33 | 0.33 |

| Elastic modulus | 62 GPa | 8990 ksi |

| Shear modulus | 25 GPa | 3630 ksi |

| Elongation at break (@thickness 1.60 mm/0.0630 in) | 5% | 5% |

| Shear strength | 74 MPa | 10700 psi |

| Hardness, Brinell (@load 500 kg with 10.0 mm ball) | 31 | 31 |

Thermal properties of aluminum 1199

| SPECIFICATIONS | CONDITIONS | ||

|---|---|---|---|

| T (°C) | TREATMENT | ||

| Electrical conductivity | 243 W / mK | 25 | O |

Properties and usage of aluminum alloy 1199

This alloy is known as ultra-pure aluminum and is used in vapor deposition coatings on surfaces of light reflectors, electrolytic capacitor foil, and chemical equipment.

Other properties of this alloy include low machinability, corrosion resistance, excellent anodizing effect, high welding and soldering capability and excellent workability.

Usages of aluminum 1199

- Food industry utensils and foils

- Heat Exchangers

- Packaging foils

- Chemical transmission equipment

-

Properties and usage of 1200 aluminum alloy

Usage Properties 1200 high purity aluminum alloy is used in the production of sheets, foils, wire and.. 1000 series aluminum has a purity of 99% (minimum). Aluminum 1200 is a malleable alloy that has high thermal conductivity and good reflectivity and corrosion resistance.

Chemical composition of aluminum alloy 1200

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | |||||||

| 1200 | Fe+Si | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Min 99 |

| <1 | <0.05 | <0.05 | – | – | <0.01 | <0.05 | <0.05 | <0.15 | |||

| ELEMENT | CONTENT (%) |

|---|---|

| Aluminum, Al | ≥ 99 |

| Silicon, Si + Iron, Fe | ≤ 1 |

| Zinc, Zn | ≤ 0.10 |

| Copper, Cu | ≤ 0.050 |

| Titanium, Ti | ≤ 0.050 |

| Manganese, Mn | ≤ 0.050 |

| Other (each) | ≤ 0.050 |

| Other (total) | ≤ 0.15 |

Physical properties of 1200 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 1200-O | 69 | 25.9 | 645 | 657 | 898 | 23.4 | 2.71 | 29.5 | 225 | 58.5 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.70 g/cm3 | 0.0975 lb/in3 |

Typical mechanical properties of 1200 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Hardship |

| O | 90 | 40 | 40 | 23 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Tensile strength | 70 – 105 MPa | 10152-15228 psi |

Aluminum equivalent alloys 1200

- Al 99.0

- Alcoa-102

- BA 99.0%

- Star-99.2

- Duricilium-T (99.0%)

- Hiduminium-1C.

Welding of aluminum alloy 1200

Aluminum 1200 can be easily welded with MIG and TIG methods. The most common filler metals are aluminum 1050 and 4043. Inert gas welding is more suitable than gas welding or resistance. Because the product is stronger and more resistant to corrosion. This alloy has very good performance.

Properties and usage of 1200 aluminum alloy

- Good corrosion resistance, good workability, high heat transfer, surface smoothness and slightly better weldability than 1050A alloy are some of the properties of this alloy.

- This alloy is used in the form of sheets, foils, wires and profiles in car license plates, identification plates, kitchen utensils, packaging foils, car decorative items, heat exchangers, radiators, as well as construction, chemical and food industries.

- Construction and gable

- Equipment and containers for food and chemical industries

- Ship structure

- Bottle cap

- Car

- Furniture and lighting

- Sound boards

- Conductive material

-

Properties and usage of aluminum alloy 1350

This alloy has good conductivity and is used in the electronics industry. 1000 series alloys such as 1350 aluminum have special usages in many industries. 1350 alloy is primarily used in the manufacture of electrical conductors and the temperature -H111 shows the highest electrical conductivity in all grades of extruded aluminum conductor, using IACS or 61.0%.

1350 Aluminum Alloy is a high alloy aluminum alloy (silicon, iron, copper, manganese and other elements). 1350 alloy is very conductive and has good ductility and leads to its use in electronics and other usages.

Properties and usage of aluminum alloy 1350

The following typical properties are not approved. Because in most cases they are calculated on average and are for different sizes and production methods and may not exactly represent any particular product or size. Although this data is certified by international standards and is a reliable source, it must be evaluated and tested before any use.

Chemical composition of aluminum alloy 1350

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | |||||||

| 1350 | Si+Fe | Cu | Mn | Mg | Cr | Zn | Ti | B<0.05Ga<0.03 | Each | Total | Min 99.5 |

| <1 | <3.3-4.6 | <0.5-1 | <0.4-1.8 | <0.1 | <0.8 | <0.2 | <0.03 | <0.1 | |||

Physical properties of aluminum alloy 1350

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 1350-O | 69 | – | 646 | 657 | 900 | 23.6 | 2.705 | 27.9 | 234 | 61.8 |

| 1350-H19 | 69 | – | 646 | 657 | 900 | 23.6 | 2.705 | 28.2 | 230 | 61 |

Typical mechanical properties of aluminum alloy 1350

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase |

| O | 83 | 28 | 55 |

| H12 | 97 | 83 | 62 |

| H14 | 110 | 97 | 69 |

| H16 | 124 | 110 | 76 |

| H19 | 186 | 165 | 103 |

Standard alloys of aluminum alloy 1350

Generally 1000 series of aluminum alloys are produced at this standard temperature :

- F :There is no special control over thermal conditions and there are no restrictions on mechanical properties.

- O – Annealing : Used for products that are resistant to the lowest temperatures.

- H111 & H112 : Hardens the pressure using the extrusion process.

Properties and usage of aluminum alloy 1350

This alloy is known as the Aluminum (EC) brand for the electrical industry and is used to make sheets, wires, rods, tubes, extruded profiles, transmission lines, bus bars, bus conductors (high pressure fittings), belts and tape for transformers. High pressure and… is used.

Due to its high purity of 99.5% or more of aluminum, 1350 is a component of “EC” or “Conduct Electric” alloys. 1350 alloy is used in a number of electrical and other industries due to its high conductivity and ductility.

2000 series of aluminum alloys

The 2000 series of aluminum alloys consists of two main elements, aluminum and copper, along with other alloying elements. The characteristics of this series of alloys include high strength, high hardness, good weldability, high fracture resistance and low casting capability. These properties can be improved by adding alloying elements such as magnesium and silver

The 2000 series of aluminum alloys can be used in the aerospace industry, aircraft and spacecraft construction, truck construction, and rivets or screws in various parts

-

Properties and usages of aluminum alloy 2007

Properties and usages of 2007 aluminum alloy mostly include excellent machining of this grade of aluminum.

Chemical composition of aluminum alloy 2007

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | |||||||

| 2007 | Fe+Si | Cu | Mn | Mg | Cr | Zn | Ti | Pb : 0.8-1.2Bi<0.2

Ni<0.2 Sn<0.2 |

Each | Total | Rem |

| <1 | <3.3-4.6 | <0.5-1 | <0.4-1.8 | <0.1 | <0.8 | <0.2 | – | <0.3 | |||

Physical properties of aluminum alloy 2007

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2007-T3, T4 | 72.5 | 27.3 | 510 | 640 | 856 | 23 | 2.85 | 51 | 130 | 34 |

Typical mechanical properties of 2007 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Hardship |

| T3 | 460 | 360 | 11 | 115 |

| T4 | 97 | 83 | 62 | – |

Properties and usages of aluminum alloy 2007

This alloy has excellent machining properties, very high cutting speed, low corrosion resistance, high toughness and strength and very high heat treating properties.

It is used in various machined components, screws, fittings and various parts, and can be produced in different shapes of pipes, sheets, wires, tubes and..

-

Properties and usages of aluminum alloy 2011

Properties and usages of aluminum alloy 2011 offers this alloy for extrusion of various sections with good machinability.

Aluminum alloys have strong corrosion resistance. These alloys are considered as suitable low temperature alloys. Because their resistance increases when exposed to ground temperature, they lose some of their resistance when exposed to high temperatures.

Aluminum alloys are sensitive to high temperatures between 200 and 250 degrees Celsius (392 and 482 degrees).

Chemical composition of aluminum alloy 2011

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2011 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Pb : 0.2-0.6 | Each | Total | Rem |

| <0.4 | <0.7 | <5-6 | – | – | – | <0.3 | – | <0.05 | <0.15 | |||

| ELEMENT | CONTENT (%) |

|---|---|

| Aluminum, Al | 93.7 |

| Copper, Cu | 5.5 |

| Bismuth, Bi | 0.4 |

| Lead, Pb | 0.4 |

Physical properties of aluminum alloy 2011

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2011-T3, T4 | 70 | 26 | 541 | 638 | 864 | 23.1 | 2.82 | 44 | 152 | 39 |

| 2011-T8 | 70 | 26 | 541 | 638 | 864 | 23.1 | 2.82 | 38 | 173 | 45 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.82 g/cm3 | 0.1018 lb/in3 |

Typical mechanical properties of 2011 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | shear strength | Percentage increase | Hardship |

| T3 | 379 | 296 | 221 | 15 | 95 |

| T4 | 407 | 310 | 241 | 12 | 100 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

The aluminum alloy equivalents of 2011 are :

- ASTM B210

- ASTM B211

- DIN 3.1056

- QQ A-225/3

- SAE J454

Manufacture and heat treatment of aluminum alloy 2011

-

Heating

Aluminum 2011 is stored for 2 to 3 hours at 413 degrees Celsius (775 degrees Fahrenheit) and then cooled to 100 degrees Celsius (50 degrees Fahrenheit) at 260 degrees Celsius (500 degrees) per hour in a controlled manner. Fahrenheit) and eventually cools in the air.

-

Welding

Welding is not recommended for 2011 aluminum.

-

Forming

The 2011 aluminum alloy can be heated between 288 and 482 degrees Celsius (550 and 900 degrees Fahrenheit).

-

shaping

Conventional methods are used to shape, bend and shape the 2011 aluminum alloy. This alloy has hardened after cooling due to the increase in strength.

-

Machining

2011 Aluminum Alloy is a machining alloy. High speed steel tools and carbide tools can be used for this alloy. Applause angles should have a cutting edge of 32 degrees and 15 degrees to the right. Light cutting can be dried and heavy cutting can be done using oils.

-

Heat treatment

The 2011 aluminum alloy is used to achieve optimum strength at 510 ° C (950 ° F). After complete heat treatment, this alloy is cooled with water and works as desired. Finally, it is heated at 160 degrees Celsius (320 degrees Fahrenheit) for 15 hours and then cooled in air.

-

Temper

The 2011 aluminum alloy hardens at 510 degrees Celsius (950 degrees Fahrenheit) and then the water is extinguished. The alloy can also be heated to 160 degrees Celsius (320 degrees Fahrenheit) for 14 hours after heating the solution to produce the temperature of T8.

-

hard working

Aluminum 2011 hardens for 3 hours at 510 degrees Celsius (950 degrees Fahrenheit) and then cools with water.

Properties and usages of alloy 2011

Aluminum 2011 is used in the manufacture of machine parts, screw machine products, pipe fittings, pipe branches, hose parts. This alloy is used in the manufacture of rods, wires, pipes and extruded profiles, stretched pipes, rebars, and also in cases that require good machining properties and strength.

-

Properties and usages of aluminum alloy 2014

Properties and usages of aluminum alloy 2014 include strong corrosion resistance and high electrical conductivity, and therefore it is widely used for the production of industrial sections, plates and sheets. The strength of these alloys increases at lower temperatures, and when these alloys are exposed to high temperatures, their strength is lost.

Aluminum alloys are suitable for low temperatures and are sensitive to high temperatures in the range of 200 to 250 degrees Celsius (392-482 ° F).

Chemical composition of aluminum alloy 2014

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2014 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.5-1.2 | <0.7 | <3.9-5 | 0.4-1.2 | 0.2-0.8 | <0.1 | <0.25 | <0.15 | <0.05 | <0.15 | |||

| Alclad 2014Coating with 6006 | 0.2-0.6 | <0.35 | 0.15-0.3 | 0.05-0.2 | 0.45-0.9 | <0.1 | <0.1 | <0.1 | – | <0.05 | <0.15 | Rem |

Physical specifications of aluminum alloy 2014

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2014-O | 72.4 | 28 | 507 | 638 | – | 22.5 | 2.8 | 34 | 192 | 50 |

| 2014-T6 | 72.4 | 28 | 507 | 638 | – | 23.4 | 2.8 | 43 | 155 | 40 |

Mechanical properties of aluminum alloy 2014

| Alloy name | Type of heat treatment | Tensile strength | Surrender strength | Increase the sample length by 0.5 inches | Hardship | shear strength | Fatigue strength |

| 2014 | O | 186 | 97 | 125 | 18 | 45 | 90 |

| T4 | 427 | 290 | 260 | 20 | 105 | 140 | |

| T6 | 483 | 414 | 240 | 13 | 135 | 125 | |

| Alclad 2014 | O | 172 | 69 | 125 | 21 | – | – |

| T3 | 434 | 276 | 255 | 20 | – | – | |

| T4 | 421 | 255 | 255 | 22 | – | – | |

| T6 | 469 | 414 | 285 | 10 | – | – |

Alloy heat treatment conditions 2014 | Alclad 2014

To perform T6 operations for products such as plates, wires, rods, sheets should be stored at 160 degrees Celsius for about 18 hours. Forged parts need to be stored at 171 ° C for 10 hours. The dissolution temperature of this alloy is 502 degrees Celsius and its annealing temperature is 413 degrees Celsius.

Other characteristics of aluminum alloy 2014

Materials similar to aluminum alloy 2014 are listed in the table below.

| ASTM B210 | ASTM B211 | ASTM B221 | ASTM B241 | ASTM B247 |

| ASTM BB241 | DIN 3.1255 | MIL T-15089 | QQ A-200/2 | QQ A-225/4 |

| QQ A-250/4 | QQ A-367 | SAE J454 |

Annealing aluminum alloy 2014

Aluminum alloy 2014 can be neutralized at 413 degrees Celsius (775 degrees Fahrenheit) for 2 to 3 hours. The alloy is then cooled between 10 and 260 degrees Celsius (50 and 500 degrees Fahrenheit) every hour, followed by cooling.

2014 aluminum alloy welding

Gas consumption arc method is recommended for 2014 aluminum alloy. Solid rods or 2017 alloy or 2014 alloy are used in the welding process. Fixturing is set to a minimum of strength because the alloy breaks during the welding process.

Forging aluminum alloy 2014

Aluminum 2014 alloy can be forged between 399 and 454 degrees Celsius (750-850 ° F).

Forming of aluminum alloy 2014

Conventional methods are used to form the 2014 aluminum alloy. The forming process is performed in T3 or T4 and a narrow bending radius is not recommended for this welding process.

Machining feature of aluminum alloy 2014

Aluminum alloy 2014 has the ability to operate in neutral conditions and the use of kerosene or oil for this machining process is recommended. The use of a 20-degree roller, a 10-degree smoothing and a 15-degree high roller are essential for cutting and turning.

Heat treatment of aluminum alloy 2014

Aluminum Alloy 2014 The alloy is heated to 502 ° C (935 ° F) and then cooled. As a result of this heat treatment, a temperature of T4 is produced.

Hardening of aluminum alloy 2014

The alloy is cured by heat treatment at 502 ° C (935 ° F). The alloy is then diluted with water to produce T4 heat.

Excess cold work after the hardening process of this alloy, causes the temperature to rise. T6511 and T6510 are produced by heat treatment at 160 ° C (320 ° F).

Asage of aluminum alloy 2014 / Alclad 2014

This alloy is used for usages that require high strength and hardness at high temperatures, for example, the following :

- Extruded profiles

- Heavy forging sheets and parts

- Widely used in aircraft parts such as wheels, fittings and main aircraft structures

- Various parts in military and defense industries

- Car suspension parts

- Truck frame

- Rods

- the wire

- Pipe

-

Properties and usages of 2024 aluminum alloy

Production of extruded sheets, rods, wires, pipes and profiles, aircraft fuselage and… are some of the usages of this aluminum alloy. Aluminum alloys have corrosion resistant properties. These alloys are sensitive to high temperatures between 200 and 250 ° C (392-482 ° F).

The strength increases when these alloys are exposed to low temperatures and high temperatures, and the strength is lost when these alloys are exposed to high temperatures. Good aluminum alloys are low temperature alloys.

Chemical composition of aluminum alloy 2024

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2024 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.05 | <0.5 | <3.8-4.9 | 0.3-0.9 | 1.2-1.8 | <0.1 | <0.25 | <0.15 | <0.05 | <0.15 | |||

| Alclad 2024

Coating with 1230 |

Si + Fe <0.7 |

<0.1 | <0.05 | <0.05 | – | <0.1 | <0.03 | – | <0.05 | <0.15 | Rem | |

Physical properties of 2024 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2024-O | 72.4 | 28 | 502 | 638 | 875 | 22.9 | 2.77 | 34 | 190 | 50 |

| 2024-T3,502 T36, T351, T361, T4 | 72.4 | 28 | 502 | 638 | 875 | 23.8 | 2.77 | 57 | 120 | 30 |

| 2024-T861, T851, T81, T6 | 72.4 | 28 | 502 | 875 | 238 | 2.77 | 2.77 | 45 | 151 | 38 |

Mechanical properties of 2024 aluminum alloy

| Alloy name | Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | shear strength | Fatigue strength |

| 2024 | O | 185 | 75 | 20 | 47 | 90 |

| T3 | 485 | 345 | 18 | 120 | 140 | |

| T4, T351 | 470 | 325 | 20 | 120 | 140 | |

| T361 | 495 | 395 | 13 | 130 | 125 | |

| Alclad 2024 | O | 180 | 75 | 20 | – | – |

| T3 | 450 | 310 | 18 | – | – | |

| T4, T351 | 440 | 290 | 19 | – | – | |

| T361 | 460 | 365 | 11 | – | – | |

| T81 | 450 | 365 | 6 | – | – | |

| T861 | 485 | 455 | 6 | – | – |

Thermal treatment conditions of Alclad 2024 / Alclad 2024 The annealing temperature of this alloy is 413° C and its dissolution temperature is 493° C. To perform aging operation,T6 or T8 should be stored at 191° C for 8-16 hours.

Other characteristics of 2024 aluminum alloy

The equivalent materials of 2024 aluminum alloy are given in the table below :

| AMS 4037 | AMS 4120 | AMS 4192 | AMS 7223 | ASTM B209 |

| ASTM B210 | ASTM B211 | ASTM B221 | ASTM B241 | ASTM B316 |

| ASTM F467 | ASTM F468 | DIN 3.1355 | MIL B-6812 | QQ A-430 |

| MIL T-50777 | QQ A-200/3 | QQ A-225/6 | QQ A-250/4 | MIL T-15089 |

| SAE J454 | QQ WW-T-700/3 |

How to produce and heat treatment of aluminum alloy 2024

-

Alloying aluminum alloy 2024

Aluminum 2024 alloy is cooled from a temperature of between 399 and 427 ° C (750 and 800 F) for about 2 hours and then slowly cooled in a furnace. This alloy can be cooled between cold operations with a temperature of 343 ° C (650 F) 2 hours after the alloy has cooled in air.

Common methods are used to work aluminum 2024 aluminum alloy. Suitable for a sheet that is 1/4’s thick, or a bend radius thinner than 1/2 to 1 times the thickness. Ductility in annealing conditions is best suited for this alloy. Radius bends five to six times the thickness are suitable for T3

-

Welding aluminum alloy 2024

In order to weld 2024 aluminum alloy, the arc method of inert gas electrodes or resistance welding is used. In general, welding of any kind is not recommended for 2024 aluminum due to the reduction of corrosion resistance due to welding heat.

-

Forming of aluminum alloy 2024

Aluminum 2024 alloy can be forged, but a reasonable corrosion resistance must be maintained using subsequent operating heat. Conventional methods are used to form 2024 aluminum alloys. Hot forming is not recommended for this alloy.

-

Machining of aluminum alloy 2024

2024 alloy has good machining properties in thermal conditions. This alloy also has good machining properties in freezing conditions. Oil lubricants should be used in the machining process.

-

Heat treatment of aluminum alloy 2024

The 2024 alloy has a hard sex and is strengthened during the heat treatment process. Condition T6 When the alloy is heated to 493 ° C (920 F) and then cooled to 190 ° C (375 F) for 10 h and cooled in air. Condition T4 When the alloy is heated to 493 ° C (920 F) and then cold water is cooled and finally aged at room temperature.

-

Edging Aluminum Alloy 2024

Condition T6 is achieved by heating the 2024 aluminum alloy to 493 ° C (920 F), then cooling the water, reheating it to 190 ° C (375 F), and finally cooling the alloy in air.

Condition T4 is obtained by heating the alloy to 493 ° C (920 F) and then cooling the cold water. Edging eventually occurs at room temperature.

Usage of 2024 aluminum alloy

This alloy is used in the form of extruded sheets, rods, wires, pipes and profiles for making pipes, aircraft structures, rivets, screws and various other structural usages.

-

Properties and usage of aluminum alloy 2030

Aluminum alloy 2030 is made specifically for machining usages. This alloy is famous for its excellent machining properties and short chips. Among aluminum alloys for high-speed automatic lathes, 2030 and 2007 have the highest mechanical properties.

This alloy is chosen most of the time when we need to have a good combination of machinability and mechanical properties. In addition, 2030 has low resistance to corrosion. Therefore, it is recommended to use the protective anodizing of the final products.

Properties and usage of 2030 aluminum alloy

Usage Aluminum with 2030 copper alloy Despite the mechanical properties, screws, studs, washers, flanges and parts that require high mechanical properties such as cylinders and hydraulic pistons are made.

The main usages of this alloy :

-

Bolt

-

String rods

Chemical compounds of aluminum alloy 2030

| CHEMICAL ELEMENTS | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| MIN | – | – | 3.3 | 0.2 | 0.5 | – | – | – | – |

| MAX | 0.8 | 0.7 | 4.5 | 1 | 1.3 | 0.1 | 0.5 | 0.2 | Rest |

Aluminum 2030 (AlCu4PbMg, A92030)

Aluminum 2030 is a 2000 series aluminum alloy: the main additive is copper alloy and is formulated for pre-formed products. By European standards, it is given as EN AW-2030. AlCu4PbMg is the chemical name for EN. A92030 is a UNS number. In addition, the name AFNOR (French) is A-U4Pb.

International standards for aluminum alloy 2030

| USA | SPAIN | FRANCE | GERMANY | GB | SWEDEN | SWITZERLAND | CANADA | ITALY |

| AA | A | AFNOR | DIN (1712-1725) | BS | SIS | VSM | ALCAN | UNI |

| 2030 | L-3121 | A-U4Pb | AlCuMgPb | 2L25 | 4335 | 200 | – |

Aluminum alloy heat treatment conditions 2030

- Baking : 380 ° C to 420 ° C for 1 to 2 hours. Slow cooling

- Placement in solution : 475 º C ± 5 ° C

- Cooling in cold water (maximum 70 degrees Celsius)

- Maturity : T3 / T4 states, at least 4 days at 20 ° C

- To obtain parts : 380 ° C to 460 ° C

2030 Aluminum Alloy Alloys

| 2007 (AlCu4PbMgMn, 3.1645, A92007) Aluminum | 2017A (AlCu4MgSi(A), 3.1325, H14) Aluminum |

| 2024 (AlCu4Mg1, 3.1355, 2L97, A92024) Aluminum | 2017 (AlCu4MgSi, A92017) Aluminum |

| 2014 (AlCu4SiMg, 3.1255, A92014) Aluminum | 2124 (2124-T851, AlCu4Mg1(A), 3.1354) Aluminum |

-

Properties and usage of aluminum alloy 2036

Aluminum is about one-third the weight of steel, copper, iron, or brass . This metal is non-toxic, non-weldable, non-combustible and non-magnetic. 2036 aluminum alloy is made of aluminum. It is a strong hardware alloy with copper which is the main element of the alloy.

Chemical composition of aluminum alloy 2036

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2036 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.5 | <0.5 | <2.2 | 0.1-0.4 | 0.3-0.6 | <0.1 | <0.25 | <0.15 | <0.05 | <0.15 | |||

Mechanical properties of 2036 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Hardship |

| T4 for sheets with a thickness of 0.64 – 3.18 mm | 290-340 | 160-195 | 20-24 | 80 |

Physical properties of aluminum alloy 2036

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2036-O | 70.3 | – | 554 | 649 | 882 | 23.4 | 2.75 | 33.2 | 198 | 52 |

| 2036-T4 | 70.3 | – | 554 | 649 | 882 | 23.4 | 2.75 | 42.1 | 159 | 41 |

Thermal properties of aluminum alloy 2036

The thermal properties of 2036 aluminum alloy are presented below.

| PROPERTIES | CONDITIONS | ||

|---|---|---|---|

| T (°C) | TREATMENT | ||

| Thermal conductivity | ۱۹۸ W / mK | ۲۵ | O |

Heat treatment conditions of 2036 alloy for annealing, this alloy should be kept at 385 for 2-3 hours. The dissolution temperature of this alloy is 499 degrees Celsius.

2036 alloy usages

Used as a sheet for car panels. Due to the sensitivity to cracking and also the reduction of mechanical properties and corrosion during welding, the welding ability of this alloy under shielding gas is limited, but in the manufacture of car parts using resistance welding, good quality can be achieved in production.

-

Properties and usage of aluminum alloy 2048

Properties and usages Aluminum alloy 2048 with its chemical composition, suitable physical and mechanical properties has made it possible to manufacture parts and structures of military equipment. Aluminum 2048 is an alloy with good corrosion resistance.

Chemical composition of aluminum alloy 2048

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2048 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.15 | <0.2 | 2.8-3.8 | 0.2-0.6 | 1.2-1.8 | – | <0.25 | <0.1 | <0.05 | <0.15 | |||

Physical properties of 2048 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2048-T851 | 72 | – | – | – | 926 | 23.5 | 2.75 | 40.3 | 159 | 42 |

Typical mechanical properties of 2048 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Elastic modulus |

| 25 | 457 | 416 | 8 | 70.3 |

| 120 | 414 | 392 | 13 | 68.3 |

| 175 | 354 | 338 | 14 | 64 |

| 260 | 234 | 219 | 10 | 57 |

Properties and usage of aluminum alloy 2048

It is used in the form of sheets and plates for the construction of components and structures in the aerospace industry and military equipment.

-

Properties and usage of aluminum alloy 2090

Grade 2090 aluminum is used to make aircraft parts. Pure aluminum is a shiny white silver metal. The distinctive feature of this metal is its light weight. Although aluminum alloys are strong, they can be easily worked. Because it is very soft and flexible. Aluminum Alloy 2090 is an alloy made with heat capability that can be easily welded.

Chemical composition of aluminum alloy 2090

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2090 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr : 0.08-0.15Li : 1.9-2.6 | Each | Total | Rem |

| <0.1 | <0.12 | 2.4-3 | <0.05 | <0.25 | <0.05 | <0.1 | <0.15 | <0.05 | <0.15 | |||

Physical properties of 2090 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2090-T81 | 76 | – | 560 | 650 | 1203 | 23.6 | 2.59 | – | 84-92 | 17-19 |

Typical mechanical properties of 2090 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase |

| T81 | 517 | 470 | 3 |

Thermal properties of aluminum alloy 2090

The thermal properties of 2090-T83 aluminum are tabulated below.

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Thermal expansion co-efficient (@20-100°C/68-212°F) | m/m°C | 13.1 µin/in°F |

| Thermal conductivity | 88 W/mK | 611 BTU in/hr.ft².°F |

Properties and usage of aluminum alloy 2090

Aluminum 2090 is mainly used in areas where high strength such as aircraft parts are required.

Usages of aluminum 2090

This alloy is used in the manufacture of sheets, forged and extruded parts, aerial structures, aircraft main structures and reservoir structures operating at sub-zero temperatures. The fuselage of passenger and warplanes and items that require a lot of modification are other uses of this alloy.

Some aircraft parts made of 2090-T83 aluminum alloy :

- Aircraft fittings and bolts

- The edges of the wings and nose

- Large body structures

-

Properties and usage of aluminum alloy 2124

Properties and usage Aluminum 2124 alloy is suitable for construction in the fuselage due to the mechanical and physical properties of this grade. Aluminum alloys have strong corrosion resistance properties. These alloys are defined as low temperature alloys with high electrical conductivity.

Aluminum alloys resist exposure to groundwater and lose their strength when exposed to high temperatures. Aluminum alloys are sensitive to high temperatures ranging from 200 to 250 degrees Celsius (392 and 482 degrees Fahrenheit).

Chemical composition of aluminum alloy 2124

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2124 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.2 | <0.3 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | <0.1 | <0.25 | <0.15 | <0.05 | <0.15 | |||

| ELEMENT | CONTENT (%) |

|---|---|

| Aluminum, Al | 93.50 |

| Copper, Cu | 4.4 |

| Magnesium, Mg | 1.5 |

| Manganese, Mn | 0.6 |

Physical properties of aluminum alloy 2124

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2124-O | 72 | – | 502 | 638 | 882 | 22.9 | 2.77 | 34.5 | 191 | 50 |

| 2124-T851 | 72 | – | 502 | 638 | 882 | 22.9 | 2.77 | 44.2 | 152 | 39 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.6-2.8 g/cm3 | 0.0939-0.1011lb/in3 |

| Melting point | 510°C | 950°F |

Typical mechanical properties of aluminum alloy 2124

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase |

| -296 | 705 | 620 | 10 |

| -28 | 505 | 470 | 8 |

| 25 | 485 | 450 | 8 |

| 100 | 455 | 420 | 9 |

| 230 | 325 | 395 | 15 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Elastic modulus | 70-80 GPa | 10152-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

Alloy heat treatment conditions 2124

The dissolution temperature of the alloy is 493 degrees Celsius, the annealing temperature is 413 degrees Celsius and the aging temperature is 191 degrees Celsius.

Aluminum alloy 2124-T851

Zr + Ti limit of maximum 0.20% may be used with this alloy only for extruded products, but only if the supplier or manufacturer and the buyer agree with each other.

This agreement may be indicated, for example, by reference to a standard, letter or other device indicating the Zr + Ti limit. The reported aluminum content is calculated as the residue.

| Component | Wt. % |

| Al | 91.2 – 94.7 |

| Cr | Max 0.1 |

| Cu | 3.8 – 4.9 |

| Fe | Max 0.3 |

| Si | Max 0.2 |

| Ti | Max 0.15 |

| Zn | Max 0.25 |

| Mg | 1.2– 1.8 |

| Mn | 0.3– 0.9 |

| Other, each | Max 0.05 |

| Other, total | Max 0.15 |

Equivalent materials of 2124 aluminum alloy are :

- AMS 4221

- ASTM B209

- QQ A-250/29

- QQ A250/9

Other properties of aluminum alloy usage 2124

- Anil

Aluminum alloy 2124 is annealed at 413 ° C (775 ° F) for 2 to 3 hours. The alloys are then cooled to 10 ° C (50 ° F) per hour to 260 ° C (500 ° F) and finally cooled in air.

- Welding

Resistance welding is recommended for 2124 aluminum alloy. Arc welding and gas welding are not recommended for this alloy.

- Forming

Aluminum alloy 2124 can be made and created.

- shaping

Aluminum alloy 2124 can be formed in a limited way and extreme cold temperature is not recommended for this alloy.

- Machining

Conventional methods are used for the machining process of 2124 aluminum alloy.

Heat treatment of aluminum alloy 2124

Aluminum alloy 2124 can be dissolved at 493 ° C (920 ° F) and then quenched. Temperature T 851 When hardening is done for 12 hours at 190 degrees Celsius (375 degrees Fahrenheit) followed by air cooling.

- Harden

Aluminum alloy 2124 is cured for 12 hours at 190 ° C (375 ° F) and then cooled in air.

- Temper

Temper for aluminum alloy 2124 is when it is done at 190 ° C (375 ° F) for about 12 hours and is alloy and then cooled in air.

Usage of aluminum alloy 2124

They are used in the form of sheets with a thickness of 1.5 to 6 inches for use in aircraft structures.

-

Properties and usage of 2218 aluminum alloy

Aluminum Alloy 2218 is an alloy in the family of copper-aluminum from the 2000 series. This alloy is one of the most complex grades of the 2000 series, with a minimum weight of 88.4% aluminum. Unlike most copper-aluminum alloys, the 2218 is a high-performance alloy with a relatively low strength of 255 MPa in terms of 2000 series alloy strength.

Despite being an alloy, it has the same corrosion and oxidation resistance as marine 5000 series alloys. Although 2218 is a malleable alloy, it can be used in casting due to its granular structure and is precisely machined after casting. Welding or glue is easy to use.

To increase tensile strength at workability cost, 2218 alloy can be heat refined with the highest grades being F, T61, T71 and T72. Alternative names for alloy are 2218, A2218 and A92218 .

Chemical composition of aluminum alloy 2218

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2218 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni : 1.7-2.3 | Each | Total | Rem |

| <0.9 | <0.1 | 3.5-4.5 | <0.2 | 1.2-1.8 | <0.1 | <0.25 | – | <0.05 | <0.15 | |||

Physical properties of aluminum alloy 2218

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 2218-T61 | 74.4 | 27.5 | 532 | 635 | 871 | 22.4 | 2.8 | 45 | 148 | 38 |

| 2218-T72 | 74.4 | 27.5 | 532 | 635 | 871 | 22.4 | 2.8 | 43 | 155 | 40 |

Typical mechanical properties of 2218 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase | Hardship |

| T61 | 407 | 303 | 13 | 115 |

| T71 | 345 | 276 | 11 | 105 |

| T72 | 331 | 255 | 11 | 95 |

Properties and usage of aluminum alloy 2218

Proper performance, thermal conductivity and subsequent stability allow the 2218 alloy to be exposed to thermal shocks whenever high-precision parts are exposed. (Especially piston engine cylinders and cylinder heads)

Usages of aluminum 2218

The following are examples of usages of this alloy.

- Forged parts

- Diesel engines and aircraft pistons

- Aircraft cylinder head

- Compressor rims

- Jet engine blades

-

Properties and usage of aluminum alloy 2219

This alloy is used to build the bodies of tanks and aircraft. Aluminum Alloy 2219 is an alloy in the copper-aluminum family made from the 2000 series. Aluminum-copper alloys have high strength. But they are generally harder to resist than corrosion and welding than other types of aluminum alloys.

The strength of these alloys decreases when exposed to temperatures of about 200 to 250 ° C. However, their strength can increase at low temperatures. For less corrosion resistance, 2219 aluminum can be found in a pure alloy such as 1050. This alloy is usually used by extrusion and is not used in casting.

Chemical composition of aluminum alloy 2219

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2219 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.2 | <0.3 | 5.8-6.8 | 0.2-0.4 | <0.02 | – | <0.1 | 0.002-0.1 | <0.05 | <0.15 | |||

| 2219 Coating with 7072 |

<0.7 | <0.1 | <0.1 | <0.1 | – | 0.8-1.3 | – | – | <0.05 | <0.15 | Rem | |

Physical properties of 2219 aluminum alloy

| Type of heat treatment | Tensile strength | Surrender strength | Percentage increase |

| O | 172 | 76 | 18 |

| T42 | 359 | 186 | 20 |

| T31,T351 | 359 | 248 | 17 |

| T37 | 393 | 317 | 11 |

| T62 | 414 | 290 | 10 |

| T81,T851 | 455 | 352 | 10 |

| T87 | 476 | 393 | 10 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Density | 2.6-2.8 g/cm3 | 0.0939- 0.101lb/in3 |

| Melting point | 510°C | 950°F |

Typical mechanical properties of 2219 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| O-2219 | 73.8 | – | 543 | 643 | 864 | 22.5 | 2.84 | 39 | 170 | 44 |

| 2219-T31,T37 | 73.8 | – | 543 | 643 | 864 | 22.5 | 2.84 | 62 | 116 | 28 |

| 2219-T62,T81,T87 | 73.8 | – | 543 | 643 | 864 | 22.5 | 2.84 | 57 | 130 | 35 |

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Tensile strength | 170 MPa | 24656 ksi |

| Yield strength | 76 MPa | 1022 ksi |

| Fatigue strength | 105 MPa | 15229 |

| Elastic modulus | 70-80 GPa | 10153-11603 ksi |

| Poisson’s ratio | 0.33 | 0.33 |

| Elongation | 18% | 18% |

Thermal properties of aluminum 2219

| PROPERTIES | CONDITIONS | |

|---|---|---|

| T (ºC) | TREATMENT | |

| Thermal conductivity | 170 W / mK | 25 |

Other standards equivalent to 2219 aluminum alloy

Alternative standard names include AlCu6Mn and A92219 , which are described in the following standards:

- ASTM B 209 : Standard specifications for aluminum sheets and plates

- ASTM B 211 : Standard specifications for aluminum and round sections, rods and wires

- ASTM B 221 : Standard specifications for aluminum alloy extruded rods, rods, wires, profiles and pipes

- ISO 6361 : Aluminum sheets, straps and plates

Other titles of 2219 Aluminum Alloy include :

| AMS 4066 | ASTM B211 | ASTM B247 | MIL A-46808 | QQ A-367 |

| AMS 4068 | ASTM B221 | ASTM B316 | MIL A-8920 | QQ A-430 |

| ASTM B209 | ASTM B241 | MIL A-46118 | QQ A-250\30 | SAE J454 |

Features of construction and operation of aluminum 2219

Aluminum 2219 can be machined in annealed mode. In heating conditions, this alloy is very difficult to machine. Oil base lubrication is used for machining operations.

- shaping

Aluminum 2219 can be formed using conventional techniques.

- Welding

To prevent cracking, 2219 aluminum alloy can be welded with great care using welding and gas welding techniques. This process proposed heat treatment in order to maintain the corrosion resistance of this alloy.

- Heating

Aluminum 2219 can be heated to 538 degrees Celsius (1000 degrees Celsius) and then immersed in cold water.

- Forming

To maintain the corrosion resistance property, 2219 aluminum alloy can be used.

- Anil

Aluminum 2219 is annealed at a sufficient time at 538 degrees Celsius (1000 degrees Celsius) and then immersed in cold water.

- Temper

Aluminum 2219 can age at 190 degrees Celsius (375 degrees Celsius) for various periods of time after cooking and cooking.

- Forging

For forging, it can be tempered for 190 hours at 190 degrees Celsius (375 degrees Fahrenheit) and sheet or plate forms can be tempered at 190 degrees Celsius (375 degrees Celsius) for 36 hours, followed by cooling. Do something in the air.

Properties and usage of aluminum alloy 2219

Aluminum alloy 2219 in particular has a high resistance to breakage, is weldable and is resistant to cracking and stress. Therefore, it is widely used in the skin of supersonic aircraft and structural members. The standard space shuttle weight tank is also made of 2219 alloy. Aluminum 2219 is suitable for making structural parts that are used in high strength welding and high temperature usages.

Usages of aluminum 2219

This alloy is used to build the body of fuel tanks, structural components and shells of supersonic aircraft and.. The welding ability of this alloy is very high and it is suitable for parts that work in the temperature range of -269 degrees Celsius. This alloy has a high fracture toughness and with T8 operation, its crack resistance due to stress corrosion increases.

-

Properties and usage of 2319 aluminum alloy

Properties and usages Aluminum alloy 2319 with high copper composition is used for high strength aircraft welding wire and truck body usages. 2319 Aluminum Alloy is a malleable alloy that has excellent resistance to cracking and stresses.

This is a filler alloy made for use with 2219 aluminum. Aluminum alloy 2319 has higher strength and better flexibility than 4000 aluminum filler alloys when welding 2000 aluminum alloys. It should not be used for welding 5000 series aluminum alloys. Aluminum 2319 is an aluminum alloy that mainly contains copper (5.8-6.8%) as an alloying element.

It also contains .20% silicon, 0.0% iron, 40.0% manganese 40%, 0.02% magnesium, 0.10% zinc, 0.10-0% titanium. 20%, titanium 0.05-0.15% vanadium, 0.10-0.25% zirconium, 0.0003003% beryllium (in arc welding electrodes) and trace elements up to 0.15%.

The density of 2319 aluminum is 2840 kg / m3. This alloy was first registered in the United States in 1958.

Chemical composition of aluminum alloy 2319

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2319 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zr : 0.1-0.25V : 0.05-0.15

0.0008 > Be |

Each | Total | Rem |

| <0.2 | <0.3 | 5.8-6.8 | 0.2-0.4 | <0.02 | – | <0.1 | 0.1-0.2 | <0.05 | <0.15 | |||

Physical properties of 2319 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| O-2319 | – | – | 543 | 643 | 864 | 22.5 | 2.83 | 39 | 170 | 44 |

Mechanical properties of aluminum alloy 2319

The table below shows the physical properties of 2319 aluminum.

| PROPERTIES | METRIC | IMPERIAL |

|---|---|---|

| Poisson’s ratio | 0.33 | 0.33 |

| Elastic modulus | 70-80 GPa | 10152-11603ksi |

Thermal properties of 2319 aluminum

| PROPERTIES | CONDITIONS | ||

|---|---|---|---|

| T (°C) | TREATMENT | ||

| Thermal conductivity | 170 W / mK | ۲۵ | – |

The equivalent materials of 2319 aluminum alloy are listed below :

- AMS 4191D

- AWS A5.10.92

- ER 2319

- R 2319

Properties and usage of aluminum alloy 2319

This alloy is used to make welding electrodes and fillers for welding metals of alloy 2219. The annealing temperature of this alloy is 413 degrees Celsius. 2319 Aluminum Alloy is used as a welding wire for high strength structural aircraft and truck fuselage usages. This alloy is used to make welding electrodes and fillers for welding metals of alloy 2219. The annealing temperature of this alloy is 413 degrees Celsius.

-

Properties and usage of aluminum alloy 2618

Properties and usages Aluminum Alloy 2618 is a high-strength aluminum alloy containing copper and magnesium that is used to produce extruded and industrial climbing parts. Aluminum has high flexibility and corrosion resistance. At low temperatures, their resistance can increase. However, their resistance can be reduced at high temperatures of about 200-250 ° C.

Aluminum Alloy 2618A is a high-strength aluminum alloy containing copper and magnesium. Alloy 2618 has good machining and has a fair resistance to weather conditions.

Chemical composition of aluminum alloy 2618

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 2618 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Ni : 0.9-1.2 | Each | Total | Rem |

| 0.1-0.25 | 0.9-1.3 | 1.9-2.7 | – | 1.3-1.8 | – | <0.1 | 0.04-0.1 | <0.05 | <0.15 | |||

Physical properties of 2618 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| T61-2618 | 74.4 | 28 | 549 | 638 | 875 | 22.3 | 2.76 | 47 | 146 | 37 |

Typical mechanical properties of 2618 aluminum alloy

| Percentage increase | Surrender strength | Tensile strength | Temperature |

| 12 | 421 | 538 | -196 |

| 10 | 372 | 441 | -28 |

| 10 | 372 | 441 | 25 |

| 10 | 372 | 427 | 100 |

| 50 | 62 | 90 | 260 |

Thermal properties of 2618 aluminum alloy

The thermal properties of 2618 aluminum are given in the table below.

| SPECIFICATION | METRIC | CONDITIONS |

|---|---|---|

| Thermal conductivity (25 ° C / 77 ° F) with T61 treatment | 146 W / mK | 1013 BTU / hr.ft². ° F |

How to make and heat treatment of aluminum 2618

- Machining

Aluminum 2618 has good machining properties. It can be operated in heating conditions.

- shaping

Aluminum 2618 has the ability to form with hot and cold temperatures.

- Welding

Aluminum 2618 can be welded using various methods. Welding is not done using conventional fusion welding methods. Because the heat generated by these methods can be harmful to this alloy.

- Heat treatment

Aluminum 2618 can be operated for a sufficient time at 530 ° C (985 ° C) and then immersed in water.

- Forming

Aluminum 2618 operates at 372 to 522 degrees Celsius (700 to 970 degrees Celsius).

- Heatability

Aluminum 2618 can be operated by heating at 350 to 372 degrees Celsius (660 to 700 degrees Celsius).

- Anil

Annealing of 2618 aluminum can be done at 385 ° C (725 ° C) for 4 hours. It can then be gently cooled in the oven.

- Temper

Aluminum 2618 can be tempered at 527 ° C (980 ° C) for 24 hours and then immersed in boiling water. The heat treatment process can be repeated at 199 ° C (390 ° C) for 20 hours, followed by cooling in air.

Properties and usages of 2618 aluminum alloy

- 2618A Aluminum Alloy (2618 Aluminum) is available in plates, strips, rods, sheets, forgings and tubes.

- 2618A Aluminum (2618 Aluminum) Alloy is commonly used in aerospace and defense components.

- This aluminum is mainly used in the manufacture of aircraft engines.

Usages of 2618 aluminum alloy

This material is commonly used for pistons and rotating parts of aircraft due to its ability to work in higher temperature usages. Forging parts, pistons and aircraft engine rotating parts that operate at high temperatures are some of the usages of this alloy.

3000 series of aluminum alloys

The 3000 series aluminum alloy is composed of two main elements, aluminum and manganese, which are stronger than the 1000 aluminum alloy series. This series of aluminum alloys has properties that can be called high tensile strength, high ductility, excellent corrosion resistance, high plastic area and good weldability.

This series of alloys can be used in the manufacture of food cans, in the manufacture of vehicle radiators, in the manufacture of chemical equipment and in the manufacture of roofs.

Properties and usage of 3003 aluminum alloy

Aluminum alloy 3003, which is one of the most widely used types of aluminum. This alloy is from the series of 3000 alloys, all of which use manganese as their main alloying element, and is considered one of the best all-purpose aluminum alloys.

3003 is an alloy in the 3000 series aluminum family and is made mostly of manganese. Like other manganese-aluminum alloys, the 3003 is an all-purpose alloy with moderate strength, good performance and good corrosion resistance. Products are usually rolled and extruded with this alloy. Aluminum alloys have high flexibility and corrosion resistance. The strength of this alloy can be increased by cooling .

Alloy 3004 is commonly used in the manufacture of beverage cans. The use of this alloy is due to the thin thickness of the can. It can be made thinner by adding 1% magnesium.

Chemical composition of aluminum alloy 3003

| Alloy name | Ingredients (weight percentage) | consideration | Other elements | AL% | ||||||||

| 3003 | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | – | Each | Total | Rem |

| <0.6 | <0.7 | 0.05-0.2 | 1-1.5 | – | – | <0.1 | – | <0.05 | <0.15 | |||

| 3003

Coating with 7072 |

<0.7 | <0.1 | <0.1 | <0.1 | – | – | – | – | <0.05 | <0.15 | Rem | |

Physical properties of 3003 aluminum alloy

| Type of heat treatment | Tensile elastic modulus | Shear elastic modulus | rigid limit | melted limit | Specific Heat | Linear thermal expansion coefficient at a temperature of 100-20 degrees | Density | electrical resistance | Thermal conductivity | Electrical conductivity |

| 3003-O | 70 | 25 | 643 | 645 | 893 | 23.2 | 2.73 | 34 | 193 | 50 |

| 3003-H12 | 70 | 25 | 643 | 645 | 893 | 23.2 | 2.73 | 41 | 163 | 42 |

| 3003-H14 | 70 | 25 | 643 | 645 | 893 | 23.2 | 2.73 | 42 | 159 | 41 |

| 3003-H18 | 70 | 25 | 643 | 645 | 893 | 23.2 | 2.73 | 43.1 | 155 | 40 |